Czech ammunition manufacturer is also successful in the field of special engineer products

Secure passage through enemy obstacles, create your own obstacles, destroy reinforced concrete structures of buildings and bridges or destroy the airport runway. These are also tasks that can be performed by engineer troops using special munitions and explosive devices. It is the fast and accurate work of well-equipped engineers that can determine the success of offensive and defensive operations.

STV GROUP is one of the world's largest manufacturers of ammunition for engineer applications. At its plant in Polička, it produces, among other things, this special ammunition as part of its ammunition programme, in virtually its entire range – from plastic explosives to Bangalore Torpedo tractor charges and a complete range of directional engineer charges. In the field of plastic explosives, for example, STV GROUP is the largest producer in our country with significant export success and their special engineer charges can be found from South East Asia to Western Europe.

The largest manufacturer of plastic explosives in the country

Black Dough plastic explosive, based on pentrite, is characterised by its excellent mouldability and adhesion and is therefore used by the armed forces, police forces and for blasting in the civilian sector. Compared to plastic explosives with a hexogene admixture (RDX), such as C4, it has a lower detonation rate, but it is its plasticity, versatility and ease of use and user comfort that has led to its increasing popularity, worldwide. Because it is easily shaped, it can be used to prepare special shapes for, for example, breaking through doors or windows, destroying unexploded ordnance, or for a wide variety of other special blasting jobs, especially by special forces and engineers.

Each production batch is subjected to very strict tests, which verify that even at high temperatures there is no oil seepage, the explosive is stable even after being shot with small arms, it can be easily pricked with a detonator even in extreme climatic conditions or it can be used even after several hours of immersion in water. The adhesion of the explosive to vertical smooth glass is also tested, where the plastic explosive must remain stuck for hours or days. In addition to laboratory tests, explosives are also tested in firing tests, during which detonation velocity, induced pressure and other parameters that are crucial for the user are measured.

Drag and directional charges

A chapter in itself is the portfolio of cumulative directional charges. These are mainly used for blasting through reinforced concrete or structural steel structures. They can therefore be used to effectively destroy buildings, bridge piers, or road and rail roads. Their effectiveness lies in the so-called Munroe effect, whereby the energy of the explosion is concentrated at one point or points in a predetermined shape when the charge is detonated with a directional cap. Virtually all anti-tank ammunition works on the same principle, from RPG-7 ammunition to Hellfire missiles. Directional charges have their origins in the first half of the 20th century, when they were used to destroy enemy armored vehicles and tanks beginning in World War I. The greatest boom was then experienced by engineer charges during the Second World War or the wars in Korea and Vietnam, and thanks to their enormous effectiveness and ease of use, they have their irreplaceable place on the modern battlefield.

We can all remember the legendary scene in the movie Saving Private Ryan when, on Omaha Beach, American soldiers blow up an enemy roadblock with a Bangalore tractor charge. The Bangalore, of course in a modernised form, is also in the STV GROUP production programme. Each Bangalore Torpedo "tube" contains a 2.2 kg charge initiated by a standard detonator. Once initiated, the charge does not only cause an explosion, but the shell of the tube creates a shrapnel effect with razor-sharp shrapnel. The length of the tractor charge is six feet (182 cm) and it comes in a set of four pieces that are interconnectible with connecting modules. Thus, a length of almost eight metres can be achieved for the entire assembly. Despite the fact that the first Bangalore design was used during the First World War, in its modern form it is an extremely effective tool for cutting through obstacles such as barbed wire, or for creating safe passages through minefields.

The smallest of the STV GROUP's family of cumulative charges is the Beehive, which gets its name from its beehive-like shape. The ammunition is equipped with feet that provide optimum spacing of the conical cup from the target

to create the greatest possible directional effect of the charge, which is composed of TNT and hexogen. It is used

for destroying objects made of various building materials as well as creating craters in the ground up to a depth

of 1,500 mm.

The Hayrick demolition charge has a charge weight of 5.3 kg with a booster charge. It is wedge-shaped and even without a spacer distance, when placed on opposite sides of, for example, a bridge pier, the charge will burn through 200 mm of laminated steel plate under pressure, 250 mm under tension or 150 mm of reinforced concrete. Its advantage is that the charges can be linked to form a 'necklace' that is installed around the perimeter of the obstacle or object to be breached or destroyed. Its shape also lends itself to cutting railroad tracks and destroying transportation infrastructure.

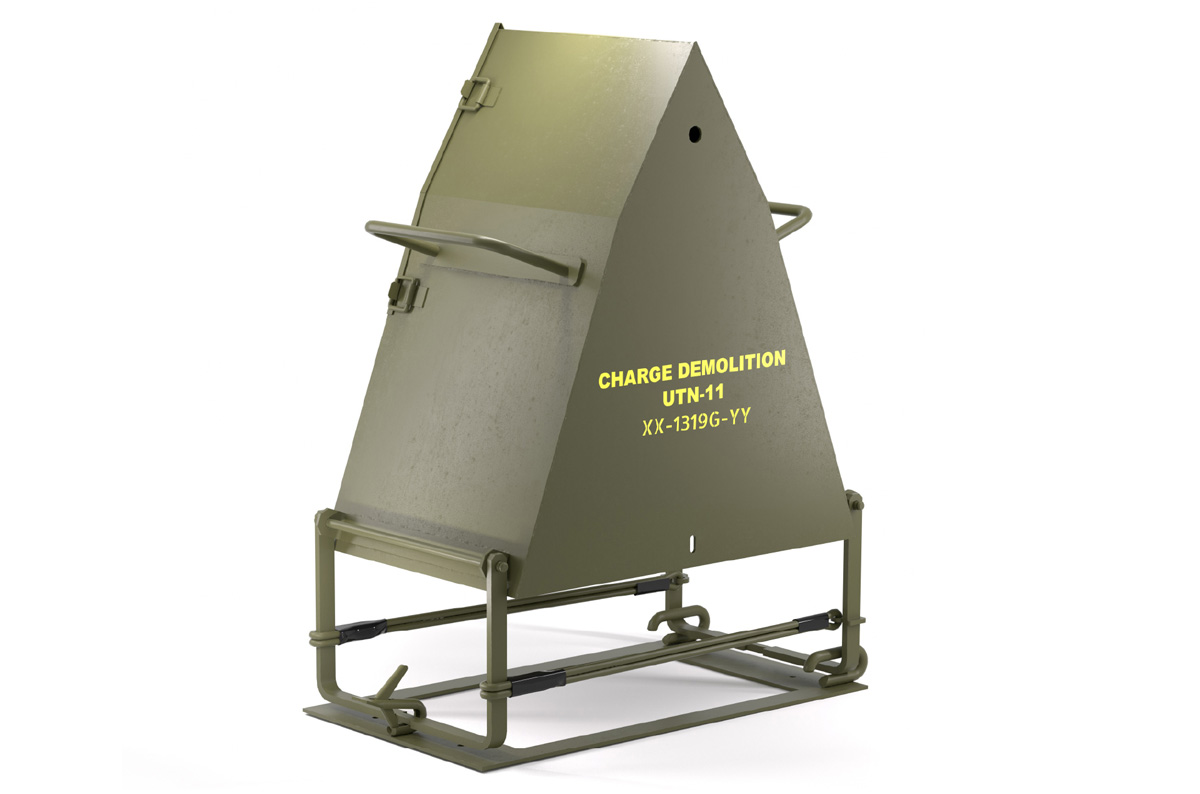

Especially against reinforced concrete objects and structures such as bridges, shelters or buildings, the UTN-11 charge with a reinforced concrete penetration of up to 1,000 mm works. It has the shape of a symmetrical wedge with parallel faces and can, like the other engineer charges mentioned, also be used as a linear charge of any length, depending on the number of charges assembled. Its total weight is almost 18 kg and only the explosive, which is a mixture of TNT and hexogen, weighs 10,5 kg.

The largest cumulative charge in STV GROUP's production portfolio is the NR-50. It is filled with a mixture of hexogen and TNT with an effective action charge for initiating a large volume of explosive. The NR-50 is equipped with folding legs to ensure clearance from the obstacle and to maximize the effect. The charge itself is designed to create cylindrical holes in the toughest materials. Efficiency in reinforced concrete is 1,500 mm, and up to 500 mm in armour plate.

A relatively new product that has emerged from STV GROUP's development and already has customers among NATO users is the Rapid Crater Kit Mk. II. It consists of the NR-50 cumulative charge, which is initiated in the first step at a selected location and creates a crater or hole. Another explosive is then inserted into the crater to multiply the effect of the explosion. The aim is to maximise structural damage, particularly to concrete and reinforced concrete structures such as airport runways.

It can therefore be used both to damage an adversary's infrastructure and to neutralize its own infrastructure as forces withdraw. The occupation of the airport of Hostomel by Russian forces in the first hours of the aggression in Ukraine comes to mind, when planes with invasion troops and material could land on a virtually intact runway.