Quittner & Schimek: A well-established supplier of wire harnesses for Defence and Aerospace Market

Recently we visited new site of Quitner & Schimek, to see how such company works, which allow us to make a report for you. Over the years Quittner & Schimek established themselves as reliable, long-term partner for well known OEMs in target markets Defence & Aerospace in Europe, but delivering also to USA, Israel and other parts of the world.

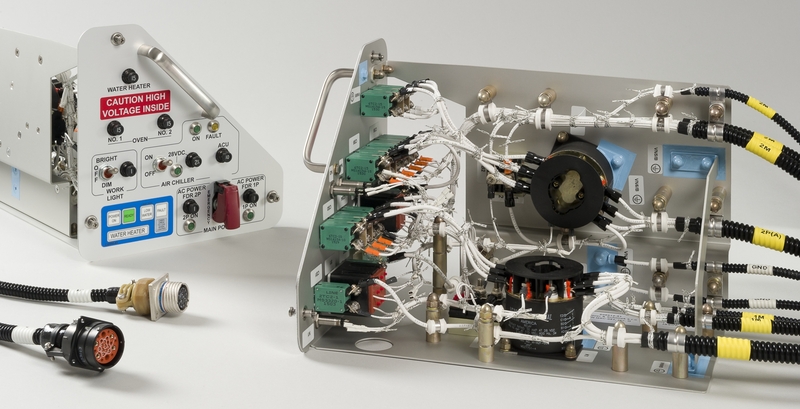

Based on the strong position in Distribution of interconnection products, wires, tools and accessories from international key manufacturers, Quittner & Schimek adds well experienced engineers to design and produce cable harnesses, panels or boxes that fly in the Eurofighter from Airbus or control the electronic in an armoured vehicle from Rheinmetall to name just some from the long list of success stories. Short term deliveries of prototypes are easily achieved by taking parts from the vast number of inventory items or simply use a connector from the own assembly shop, certified by US-DLA authorities.NA

Milos Pajr, our guide during the visit explains: “We at Quittner & Schimek provide high quality products at a reasonable price level. Customer satisfaction throughout the project has priority over profit maximization. The experience and knowledge of involved engineers and production staff results in competitive offers, increased efficiency, technical superiority accompanied by long-term cost reduction plans once a project moves into volume production. All of this helps our customers and their products to remain or become more successful in their respective markets. Our Policy is fair and square in all our activities.”

The workshops in the state of the art factory in Stará Paka is filled with busy workers. We have seen e.g. last minute production of development cables for the LAND 400 Phase 3 Project (Rheinmetall LYNX and LANCE for testing in Australia) are finalised. Also very interesting was complex and demanding assembly procedures of hybrid solutions (copper and fiber-optic cores in one cable and connector) for the upgrade of the Rheinmetall IFV PUMA program.

Picture: Milos Pajr, our guide during the visit explains: “We at Quittner & Schimek provide high quality products at a reasonable price level. Customer satisfaction throughout the project has priority over profit maximization. | archive of Quittner & Schimek

We have been surprised by the modern architecture within the building, the spacious interior of production, offices and the latest tools and machinery used in the production. Miloš Pajr points out: “We bought this site about 5 years ago and we expected to move in quite quickly from our recent factory buildings in Nova Paka. This factory was used by the previous owners for producing windows so there was enough space available that should fit all our demands but when we started detailed planning, respecting all fire and safety regulations, improving the workflow of products, trying to spice it up with ergonomic solutions here and there to make working at Quittner & Schimek more comfortable for all our employees……so in the end it took 3 years and double cost to have it all ready. Murphys law was sitting on our shoulders every day but we were growing as a company in every detail by mastering this huge project all together. Today we have fully modernised 8000 m2 in 2 halls and there are another 8000 m2 in two more currently unused halls to allow us to make install complete assembly lines for armoured vehicles or business jets.“ “But currently we are too lazy to start such new project“, Milos adds with a big smile.

Picture: We have been surprised by the modern architecture within the building, the spacious interior of production, offices and the latest tools and machinery used in the production. | archive of Quittner & Schimek

Picture: We have been surprised by the modern architecture within the building, the spacious interior of production, offices and the latest tools and machinery used in the production. | archive of Quittner & Schimek

Private owned company Quittner & Schimek started their business activities in 1991 focusing on distribution of electrical components for defence, aerospace and similar demanding markets. All leading well branded manufacturers of connectors, backshells, wires, heat-shrinkable parts, relays, contactors etc. are represented in the business activities, either in resale or production of electrical installations.

Picture: Mounting table | archive of Quittner & Schimek

Picture: Mounting table | archive of Quittner & Schimek

One unique feature of Quittner & Schimek is the inhouse Connectors Assembly Line, certified both by the Manufacturer and the US military authority DLA. It allows to assembly about 80.000 different configurations of circular US Military normed connectors as well as German military normed VG type connectors. It was the first DLA qualified workshop in central east Europe at the time and became one of the leading production site in Europe these days. Connectors are delivered to customers around the globe, quickly and without minimum order quantities.

By acquiring the first UV Laser Marking Machine in Central East Europe back in 1999 Quittner & Schimek was suddenly able to offer added value services for wire marking. Together with modern logistics they became a key supplier for company Aero Vodochody, a key supplier of civil and military aviation products. Quickly more customers saw the benefits of partnering and the expansion into the production of wire harnesses, e-panels and boxes followed soon afterwards adding over 200 new jobs locally over the past 20 years.

Picture: You can find Quittner & Schimek´s panels or boxes in Airbus or Boeing airplanes | archive of Quittner & Schimek

Picture: You can find Quittner & Schimek´s panels or boxes in Airbus or Boeing airplanes | archive of Quittner & Schimek

The sister companies Quittner & Schimek and SQS Fiber Optic became so one of most important employers of the region with around 500 employees currently on their pay-roll.

Milos Pajr continues: „Long term reliability, high quality and maximum focus on customer support are our easy but hard way to satisfy our customer base.”

We see that this strategy pays off when we look at the list of customers and projects. Within Czech Republic and Slovakia we can reference companies and projects like Aero Vodochody (L-159, A-270 IBIS, Sikorsky S-76, Blackhawk, L-39, L-39 NG, Spartan, Saab, ….), MESIT, ERA, RETIA, PBS Velká Bíteš, EVPU Defence, Konštrukta. Internationally the customer list is also very impressive, Airbus-Eurofighter, Airbus A320-380, Boeing737-777, Pilatus, Kopter to name some of them. In the market of military armoured vehicles they are successful at Rheinmetall Defence and Krauss-Maffei Wegmann (PUMA, BOXER, LYNX, LANCE, LEOPARD 2, PzH2000, Buffalo, Skyshield, Skyguard), Safran Défence, Nexter, Thales, Rafael, DND or Honeywell Aerospace.”

A very special customer became the Buggyra Racing Team. Czech origin with expanded activities all over the globe in various international racing series, Buggyra is using cable harness from Quittner & Schimek for their vehicles.

Picture: A very special customer became the Buggyra Racing Team. Czech origin with expanded activities all over the globe in various international racing series, Buggyra is using cable harness from Quittner & Schimek for their vehicles. | archive of Quittner & Schimek

Picture: A very special customer became the Buggyra Racing Team. Czech origin with expanded activities all over the globe in various international racing series, Buggyra is using cable harness from Quittner & Schimek for their vehicles. | archive of Quittner & Schimek

For sure there are a lot of new interesting projects, technologies and developments from Quittner & Schimek to follow in the next years.